摘要:这样的说法是不是太过于理所应当:确保出厂产品质量的最好方法是不犯错误?或许。那么,更不明显一点的是,如何有效地设计产品和工作流程以避免犯错。

当然,错误的考证不是免费的,不过比起运送更换部件、故障带来的停机、带来罚款为补救一些供货合同所花费的来说,还是相当低的。正如Faurecia的金属制制造部门经理David Marten所说:“如果由于一台机器停止运行或生产出不合格产品,使得我们失去半天的产品,这意味着我们面临一个大麻烦了。我们必须在错误发生前提早发现,否则就不能形成一个产业。”David Marten正与他的同事致力于避免犯错误。

英文全文如下:

How to control quality: Err not

Mark T. Hoske, editor-in-chief -- Control Engineering

Is it just too obvious to say that the best way to ensure quality products go out the door is to not make errors in the f

While error-proofing isn’t free, it can be considerably less costly than shipping the wrong parts, causing a shutdown, or triggering fines or remediation efforts built into some supply contracts, says David Marten, Faurecia manager of manufacturing metal engineering. “If we lose a half day’s production due to a machine being down or producing unacceptable product, we’re in big trouble. We have to do error-proofing, or we’re not going to make it as an industry,” Marten warns. He’s working with others to avoid mistakes.

Marten is on a subcommittee, Effective Error-Proofing Workgroup, under the Quality Steering Committee of Automotive Industry Action Group Forum (AIAG). Faurecia makes automotive seating in Troy, MI, and AIAG is making a guide to error-proofing; a draft is ready this month (December 2007). The guide is expected to be published by July.

The answer isn’t to automate everything, because for jobs with high variability and low number, people can be more cost effective.

“People are very good and very flexible in a lot of processes” where controls would be too rigid or robotics too expensive, says Marten. Robots are better for a lot of things, namely greater safety, fewer errors, and higher speeds, and their costs have dropped quite a bit, Marten explains, adding: “automation usually helps with error-proofing, but it doesn’t mean you eliminate operators. We just control the environment so humans have to do things right or the process shuts down.”

Does better quality control always increase costs? Not necessarily. A better question is, “How much does it cost when there’s a problem?” Keep solutions as simple as possible. Seek the most effective, least costly way to eliminate the chance of error. Ways to error-proof, Marten says, from most to least desirable, are to:

·Eliminate the error-prone element;

·Prevent the error;

·Detect the error and

·Detect the defect at the source; and

·Detect the defect prior to shipping.

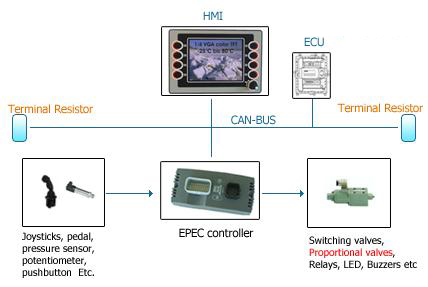

Parts and processes should be designed so things always get assembled, labeled, packaged, and shipped correctly. If the process isn’t perfect, then errors should be caught and corrected as close to the source as possible. Appropriately placed sensors, logic, and actuators can help.